Cutting and Trimming Solutions

Tosingraf offers a full, functional and safe range for any need; a wide choice from portable trimmers to professional guillotines. To ensure the utmost operator safety, all machines have the latest safety systems.

Trimmer

The sliding rotary blade can cut single sheets or thicknesses of up to a maximum of 15 sheets. Manual or electric, it is used by photocopying centres, photographic centres, engineering departments and alongside heliographic machines or plotters. The range covers portable to professional trimmers with usable openings of up to 360 cm.

Lever cutter

This is used in the office sector for cutting thickness of up to 40 sheets. A range of models offer different: usable cutting openings (necessarily greater than or equal to the surface of the printed material), paper clamp type (manual or automatic), optional backgauge to perform cuts in sequence. The range covers every need up to cut lengths of 71 cm.

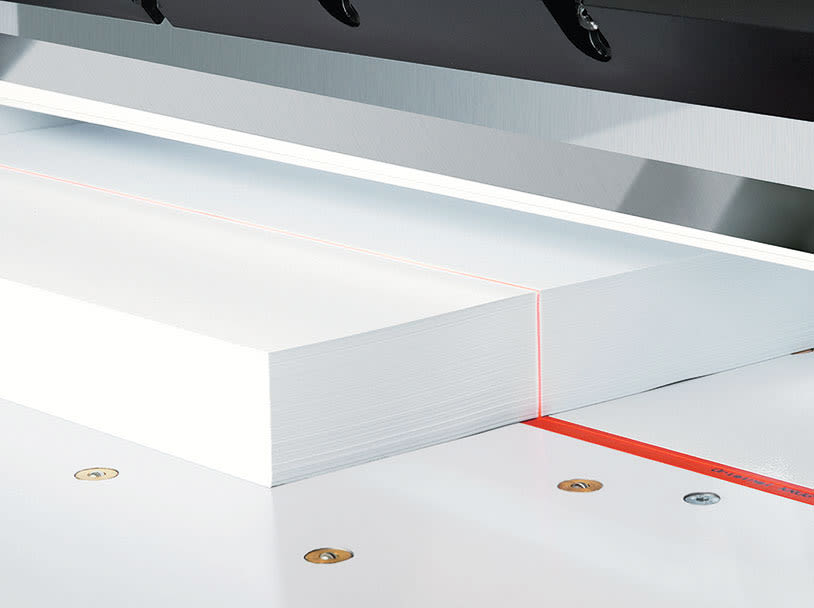

Guillotines

These cut high thickness (up to 600 sheets). The machines can be manual or electric and differ by: the maximum cut size (width and depth); maximum thickness, settable cut size, measurement adjustment type, paper clamp type (manual, electric or hydraulic backgauge movement, blade descent (manual, electric or hydraulic).

Three-side cutter

This cuts the three sides of the package that are not bound. It is used in the industrial sector to perfectly align the three side of a book.

Guillotines - IDEAL/EBA

The market offers a wide range of extremely economical guillotines. These machines, however, do not comply with current European safety regulations and therefore pose a great risk to the operator!

The electro-mechanical guillotines made by IDEAL/EBA, a German brand that is the leading cutting machine manufacturer worldwide, are equipped with the latest safety systems, which comply with the IDEAL SCS standard (Safety Cutting System):

The patented EASY-CUT system uses two manual levers to active the clamp and blade descent, ensuring the utmost operator safety;

There is a safety cover at the front and rear of the machine;

Low-voltage operating commands (24 V in accordance with the regulations);

Automatic blade return;

Disc brake to stop the blade immediately;

Main switch and key-operated safety switch;

A special device covers the cutting edge during blade replacement;

Latest generation photocells monitor the whole working area and only enable the cutting function when the area is completely free;

Certifications: CE, GS, UL.

Tips for good guillotine use and maintenance

Whether manual or semi-automatic, guillotines have mechanical moving parts that require periodic maintenance, depending on the work load to which they are subjected and in any case at least once every 6 months. The machine comes with a grease pump to lubricate the backgauge movement. It is advisable to periodically follow the instructions in the manual provided or rely on specialist technicians to: lubricate the moving parts (backgauge, clamp, blade), sharpen the blade, check that the cut is parallel; check the measurements.

Blades - sharpening angles

Sharpening is the last, usually manual, step in perfecting the blade cut. When blades are manufactured, they are sharpened after grinding to give their cutting edges the greatest cutting capacity.

Before sharpening the blade, establish its principle use in order to determine the sharpening angle. The sharpening angle is the angle between two ideal straight lines: one passing through the centre of the blade surface and the other tangential to the sharpening surface. The more acute the angle is, the sharper and more delicate the cutting edge. Increasing the angle, on the other hand, makes it stronger. The cutting edge of a razor, for example, has an angle of 10° or 12° (allowing few cuts); the cutting edge of a kitchen knife is about 30°; the cutting edge of a survival knife is from 35° to 45° (allowing many cuts); an axe has a cutting edge of 60° (allowing prolonged heavy use).

We have created this small guide to help you find the right sharpening angle for your blade.

In the table below, we have tried to gather all the materials that are most frequently used for cutting, in alphabetical order. We have divided the table into groups for the sake of clarity. All the values given are experimental, and can be considered indicative for numerous guillotine models. The pressures refer to a stack with an average height that takes up 2/3 of the cut width.

Stacks with greater heights and widths require greater pressures, while lower heights and widths require lower pressures.

Delicate materials (thin and soft) require the standard clamp pad; materials that are corrugated or with different heights (cardboard, sewn paperback bindings) should be cut using the flexible clamp pad.

Standard angles for IDEAL/EBA blades: 21° for paper; it is possible to create an angle of 24° cut at 3.5 mm (chisel bevel) for special types of paper; we recommend an angle of 75° for cardboard.