Binding Guide

Why bind?

Binding is the easiest way to give your documents a professional look and make them easier to consult. Bound documents are easier to handle, transport, and archive. It protects them by keeping dust away and preventing the pages from curling. You can add style and colour to the document with a wide choice of spines and covers.

Which binding machine should you choose? Here are some questions you need to ask to make the right choice:

How many documents do I need to bind? If you are binding documents for personal use, you can opt for an efficient and economical system like simple plastic spines, but if there are many pages, it is better to go for a manual spiral binding machine. If instead you bind many documents every day, perhaps for your office work, then it might be convenient to buy an electric binding machine.

Why do I need to bind documents? If you need professional-looking documents for work presentations, a thermal binding machine is the best solution to create handouts and brochures with stunning customised graphics. If you need to modify the document, plastic spiral binding is preferable because sheets can be inserted, removed, or replaced. If you need to bind a calendar or handy booklet with pages that can be turned by 360° spiral binding is recommended.

What other things should I consider? Assess the following factors to decide which binding machine is best for your needs:

Hole punching capacity, the maximum number of sheets that can be punched at once;

Two separate levers, one for punching and one for binding, offer greater speed and efficiency;

Option to disable punches, makes it possible to centre the holes even on non-standard sizes, and can create spiral-bound calendars (leaving a free gap in the middle for the semi-circular cut);

Adjustable hole depth from the margin, makes it easier to turn pages and holds them better;

Spine opening stop, helps to speed up insertion of spirals with the same diameter.

Blokcart slide binders

Simple and economical, elegant and linear, Blokcart slide binders are used above all for posters and calendars. It has a chamfer to make it easier to insert the sheets by hand. It is available in a range of colours, can be cut as required, is reusable and can be used with a hanger. It has excellent grip, even with large sizes. Sheets suitable for binding: up to 110 (80 g).

Plastic comb spines

This is one of the most popular binding systems. Documents can be opened fully for reading and photocopying. The comb can be reopened to add or remove pages. It is ideal for: school essays, recipes, manuals, presentations. Choice of consumables: plastic comb spines are available in numerous sizes and colours; covers are available in various colours, thicknesses and finishes. Clear PVC is normally used for the front, while card is used for the back. Sheets suitable for binding: up to 500 (80 g).

Features of plastic comb spines:

Diameter: 5 to 50 mm;

Length: 30 cm standard (21 rings);

Hole pitch: 14.28 mm, the distance between the spine holes;

Colours: white, black, red, blue, green, yellow, grey and clear.

The Tosingraf catalogue contains electric or manual plastic comb binding machines. Manual binding machines have a hand-operated lever to punch the sheets, while electric models offer effortless automatic punching. Electric binding machines are therefore especially convenient for very intensive use. Main features:

Maximum number of sheets that can be punched at a time: 25/30 ( 80 g) for manual binding machines, 40 ( 80 g) for electric binding machines;

Structure type: plastic or metal;

Usable punching gap: maximum width of the sheets to be bound;

Option to choose the hole distance from the margin of the sheet;

Stop, to adjust the spine opening;

Structure of the punch die unit (to make the holes): this may have pyramid force, progressive punching (i.e. one hole after another in succession), or distributed force (in which punches act simultaneously at different points over the whole sheet surface);

Fixed or multi-purpose die: in professional models the die may be fixed or interchangeable, in which case the hole type can be changed to adapt the same machine to suit different needs.

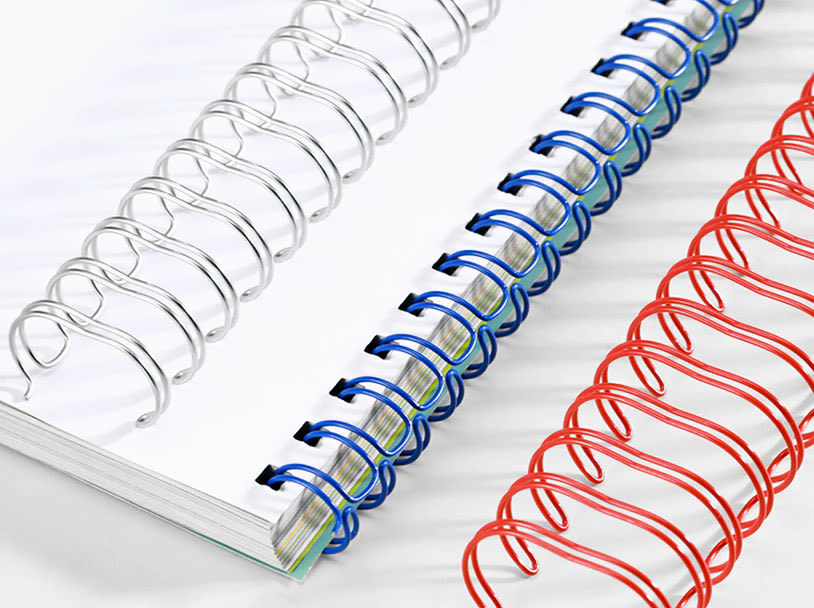

Wire-O® spirals

This gives documents a more professional finish than plastic combs. The binding is permanent and secure, the rings cannot be reopened to add pages, and pages can be turned by 360°. It is ideal for: notebooks, calendars, commercial quotations, reports, estimates, contracts, business documents in general. Choice of consumables: Wire spirals are available in the following colours: white, black, brilux, blue and red; covers are available in various colours, thicknesses and finishes. Clear PVC is normally used for the front, while card is used for the back.

Wire-O® spiral binding, the type offered by Tosingraf, allows pages to be managed and torn off individually without deforming the spiral and compromising the whole block of bound sheets. Wire-O® gives the product exceptional stability: the spiral does not simply pass from top to bottom, but after insertion into each hole, the metal wire is pressed to form an ‘O’. The perforation pitch (distance between holes) is measured in inches (1 inch = 25.4 mm). Below are the main properties:

3:1 pitch (3 holes in 1 inch): the spiral may have one of seven different diameters from 4.7 to 14.3 mm. Maximum binding capacity: 120 sheets, 34 loops in 30 cm;

2:1 pitch (2 holes in 1 inch): the spiral may have one of five different diameters from 16 to 38 mm. Binding capacity: 140 to 325 sheets, 23 loops in 30 cm.

Electric multi-die punches for Wire spirals can be fitted with any punching die in just 20 seconds; the same machine can perform any binding, to meet any need. A closing press (to close the spiral) and a spine opener (to open the spiral) can be added.

The spiral is always inserted and closed manually due to the high costs of automatic machines and their long start-up times. For binding lengths other than 30 cm, it is worth using a reel (endless spiral) in place of the spiral.

Thermal binding covers

These give documents a book-like finish. The document remains neat and flat, perfect for shipping, transport and storage. It is a hot binding technique: the glue in the thermal binding cover melts on contact with the plate in the thermal binding machine and sticks to the sheets, attaching them together. If the glue surface on the spine has a “sprayed” effect, the work is of good quality, while if it is perfectly smooth (“strip” effect), it is of high quality. It is very quick and easy to use, and gives a professional appearance with no need to punch the document. It is ideal for: essays, training manuals, reports, contracts. Choice of consumables: Pre-creased thermal binding covers with customisable sizes, thicknesses (different spines are available to suit the number of sheets to be bound) and colours on request. The PVC on the front is clear, scratch-resistant and anti-glare. Sheets suitable for binding: up to 530 (70 g). The packing boxes are appreciated because they can be reused as archive containers.

Perfect binding

Perfect binding is used for documents thicker than 3 millimetres, and can be perfect (glued) or sewn (stitched).

Perfect binding

Also known as glued paperback binding, this is the most common method for making books, catalogues and more generally all thick volumes (with more than 32 pages). The pages of the publication are held together and joined to the cover by hot melt glue (EVA) or polyurethane glue (PUR). The glue penetration process is optimised by two factors: selecting porous papers and applying additional “milling” (trimming) or “notching” (grooving) to the spine.

Sewn binding

This differs from glued binding as there is no milling. In this case, the pages are folded and collected in signatures to be sewn with cotton, flax, hemp or synthetic thread, and subsequently glued together.

The pros of perfect binding: the processing cost is certainly lower than that of sewn binding; pages up to a grammage of 115 grams are held very well; it is an ideal binding for digital printing; it offers fast delivery times.

The cons of perfect binding: it is unsuitable for thick and coated pages such as photo magazines; it is less resistant to wear; the book has a smaller opening.

Tosingraf offers a wide range of perfect binding machines. The main technical features are:

Sheet clamp, manual or automatic;

Notching station, this deliberately makes the spine of the sheets uneven so that the glue penetrates better;

Glue spreading system, from the bottom or from the top;

Cover application system, manual or automatic;

Creasing system for folding the book spine, manual or automatic.

Openable plastic spiral

This system uses a spiral of 34 plastic loops (compatible with 3:1 hole pitch), which can be opened easily with a special tool or by hand. The document can therefore be changed by adding, removing or swapping pages. These easy-to-use spines give the document a dynamic and modern look, and allow it to be opened 360 degrees, making it easy to consult and photocopy. Choice of consumables: openable plastic spiral, in various sizes. Sheets suitable for binding: up to 140 (80 g). They are also compatible with any Tosingraf metal spiral binding machine.

Covers with metal spines

This binding and the corresponding covers make documents very durable with a very professional look. The document remains neat and flat, perfect for shipping, transport and storage. The covers that can be used with this system have a metal spine, which clamps all the sheets of the document and holds them together when pressed in the special binding machine. The document can be reopened with a special tool and then changed several times. The document remains neat and flat. It is similar to thermal binding, but with the advantage of being modifiable. It is ideal for: catalogues, brochures, price lists, manuals. Choice of consumables: covers with metal spines, of various sizes and colours. Sheets suitable for binding: up to 300 (80 g).

Heat-sealing combs

In this type of binding, the needles of the combs are inserted into the sheets and the binding machine then seals them. It is therefore no longer possible to change/alter the document without leaving visible traces. The teeth are long enough to bind a large number of sheets, even veritable tomes. It is ideal for: legal documents, contracts, notarial firms, lawyers, as well as university handouts, acts, balance sheets. Choice of consumables: heat-sealing combs - These are the only combs that can be used with this kind of binding machine, and are available in various colours. Sheets suitable for binding: up to 500 (80 g).

Features of heat-sealing combs:

Positioning, sheet clamping and cutting are performed manually;

The excess part of the pin is cut and heat sealed;

When 30 cm long, it can have 4, 6, 10 or 12 pins – the most recent machine have 4 or 10;

Available in the following colours: white, black, red and blue.

Twin Snap plastic strips

With this kind of binding, the comb pins are folded back on themselves manually. Documents can be modified: just release the pins, add or remove pages and close them again. It is similar to thermal binding, but with the benefit of being able to update the pages when necessary. Choice of consumables: Twin Snap plastic strips with closed spines are available in four fixed heights (6, 10, 15 and 20 mm), in the colours white, black, red and blue. 100% compatible with plastic comb binding. Sheets suitable for binding: up to 200 (80 g).